Over the past two years, Polyram has ventured into a new field—materials for 3D printers. These are not the commonly known materials but rather those designed for the rapidly growing FGF printing technology. This technology utilizes specialty raw material pellets instead of filaments, powders, or liquid resins.

“This printing method is not yet widespread in the industry but holds significant potential,” explains Amit Koren, VP of Sales and Innovation at Polyram. “We saw this at the last Formnext exhibition, where more and more new solutions in this field were presented. There is a synergy between Polyram’s existing products, its Engineering Plastics division, and the needs of the world of FGF printing. To advance this initiative, we have built a dedicated development team.”

Challenges in FGF Printing – Why Material Selection is Critical

In FGF technology, polymer compounding is required—Polyram’s area of expertise. Compounding helps address several challenges associated with this technology, including:

- Uncontrolled crystallization during material extrusion

- The need for varying print resolutions

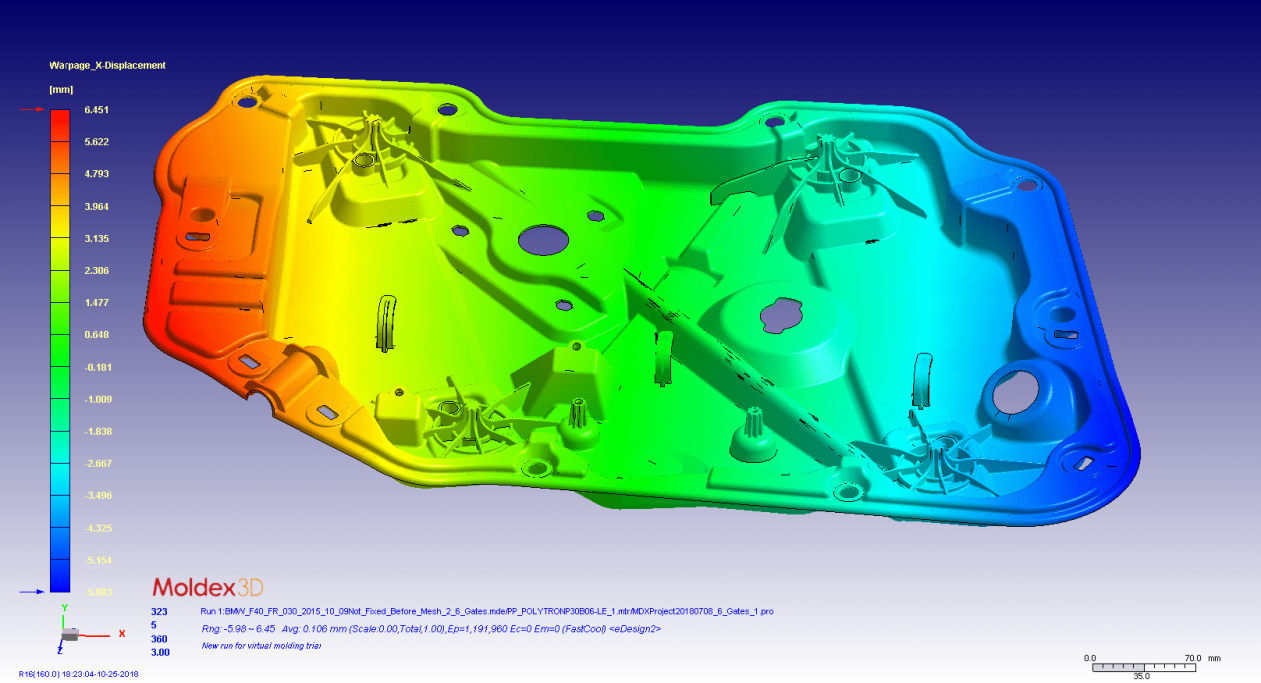

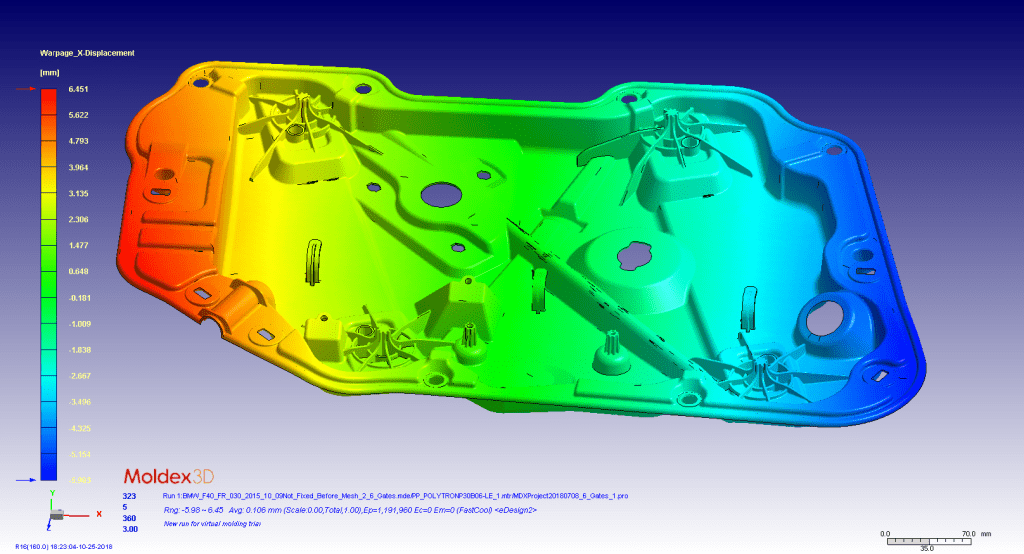

- Material shrinkage

- Layer adhesion

The surface of the final product often exhibits wavy layers. The larger the product and the wider the nozzle diameter, the more pronounced the waviness. When smooth surfaces are required, particularly with larger nozzles, post-processing is necessary to refine the finish.

What Materials Does Polyram Offer for FGF Printing?

Due to these challenges, PLA and PETG are commonly used because they offer stable and easy printing, but they often do not meet the required material properties for the final application.

“End customers often lack the knowledge and confidence to work with alternative materials. This is exactly where we come in,” says Amit. “Our compounding expertise opens the door to a broad range of materials specifically developed for this purpose. We provide our accumulated knowledge to our customers.”

Polyram’s FGF printing solutions are branded under the name Ram3D. The available materials include:

- ABS family: Offered in white (or customized colors) and reinforced with carbon or glass fibers to reduce material shrinkage.

- Additional solutions based on ABS ASA, ASA, and PC ABS.

- PA-based composites, including Nylon 12 and Nylon 6.

- PP- and PETG-based compounds with glass fibers.

Products manufactured with Polyram’s materials were also showcased at Formnext, at the booth of MODIX, an Israeli 3D printing company. The company’s Big Mama printer, capable of printing giant products up to 2 meters in height, was displayed prominently.

How to Choose the Right Material for the Customer’s Needs?

“There are no off-the-shelf materials in this field,” explains Amit. “Material selection is tailored to each specific application, considering the final product, the printer, environmental conditions, and the material properties.”

For example:

- Desktop machines have delicate, small extruders with lower shear and processing capabilities.

- Large-scale machines have massive extruders, higher output rates, and stronger shear forces.

Controlling material homogeneity and flow ensures optimal performance across different equipment types.

“Due to the sensitivity of this method, the best approach is to consult with us and provide full process details so we can recommend the right material,” emphasizes Amit. “As a first step, customers can check our website, where many solutions are available in the catalog.”

A Technology with Limitless Potential

FGF technology enables groundbreaking applications that do not exist in conventional plastic manufacturing, including construction, architecture, and large-scale products. The output can reach hundreds of kilograms per hour.

FGF printers are also used for marine applications, defense applications and even in marketing and advertising, where large-scale promotional models can be produced.

Examples of FGF-printed products in Israel include:

- Benches at Holon train station

- Large promotional items for well-known brands

- Defense-related applications supporting security forces

Targeting the European Market

“Right now, we are focusing on the European market after significantly advancing the development process. We are also strengthening our sales activities in this field,” says Amit.

“Entering a new field from scratch comes with challenges, but the potential is immense, and we are already delivering significant value.”

More Information:

Amit Koren- amit@polyram-group.com

Credit: https://plastictime.co.il/