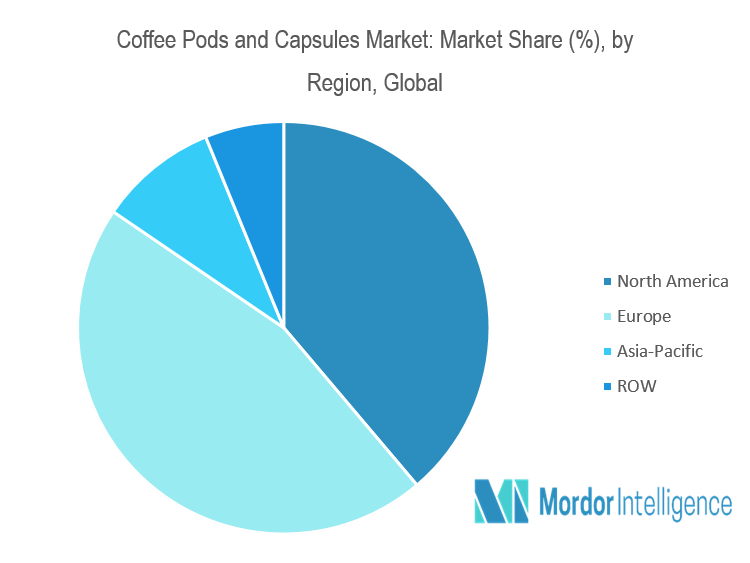

As coffee is the most consumed beverage by volume, high demand for coffee globally is one of the major factors responsible for the growing popularity of coffee pods among consumers. The reason for this market’s growth is Its one-time-use and disposable features.

What else is important for supreme coffee enjoyment? The taste and the Aroma.

In order to preserve high quality, there is a need for supreme barrier properties pod packages.

The Aluminum pod gives the ultimate barrier properties along with a list of disadvantages (such as costs, energy consumption, recycle challenges and more).

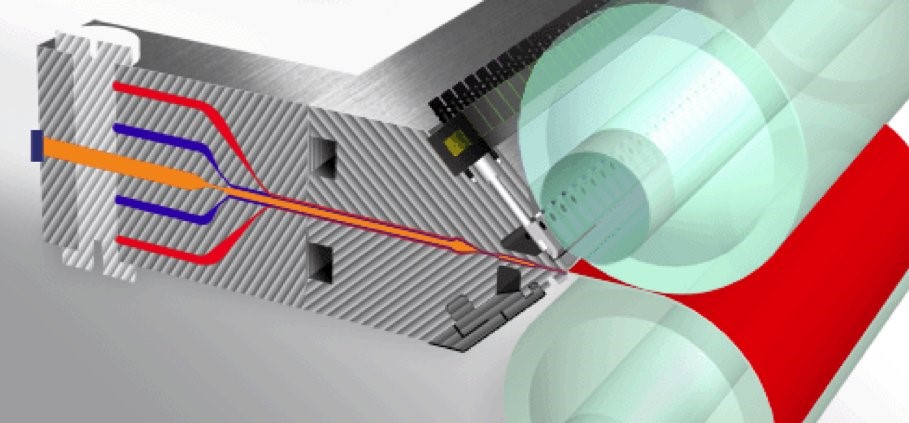

The second option is high barrier plastics pods using co-extrusion thermoform sheet.

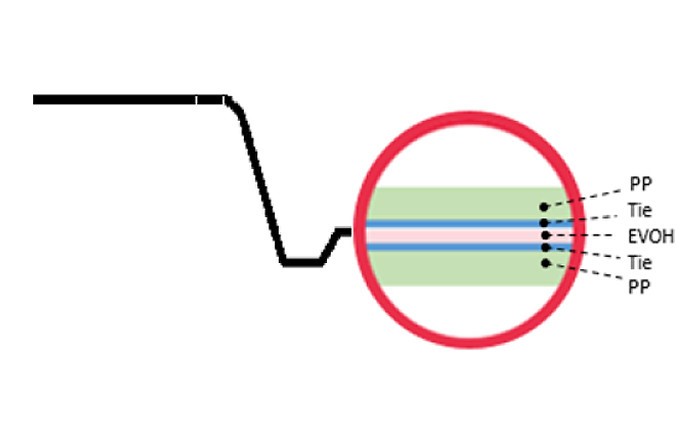

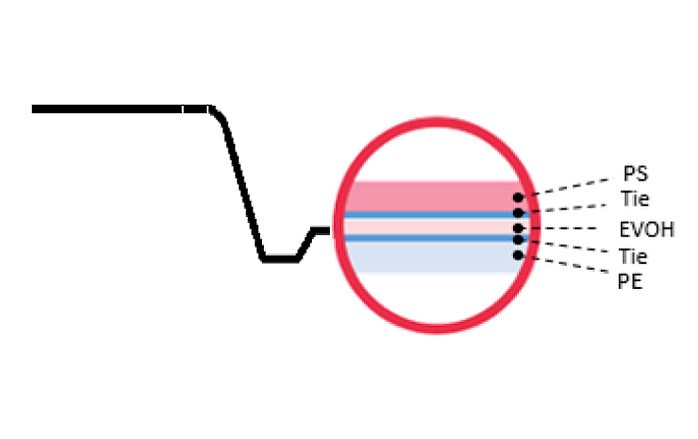

There are two base polymers structures:

Multi-layer High barrier Polypropylene PP/TIE/EVOH/TIE/PP

This symmetric structure provides a better heat resistance and a recycle friendly formulation.

Polyram offers Bondyram® TL1235 and Bondyram®TL1236 Resin for this application (Polypropylene based product).

Multi-layer High barrier Polystyrene – HIPS/TIE/EVOH/TIE/PE

This non symmetric structure demands one tie-layer adhesive resin with good adhesion for HIPS, PE and EVOH.

Polyram offers Bondyram® TL4402 for this application which demands high VICAT properties (above 80⁰C), high adhesion in one product to all three different polymers.

Now days, Polyram sells thousands of tons of Bondyram® TL to the main producers of the coffee capsules in North America.